Processes

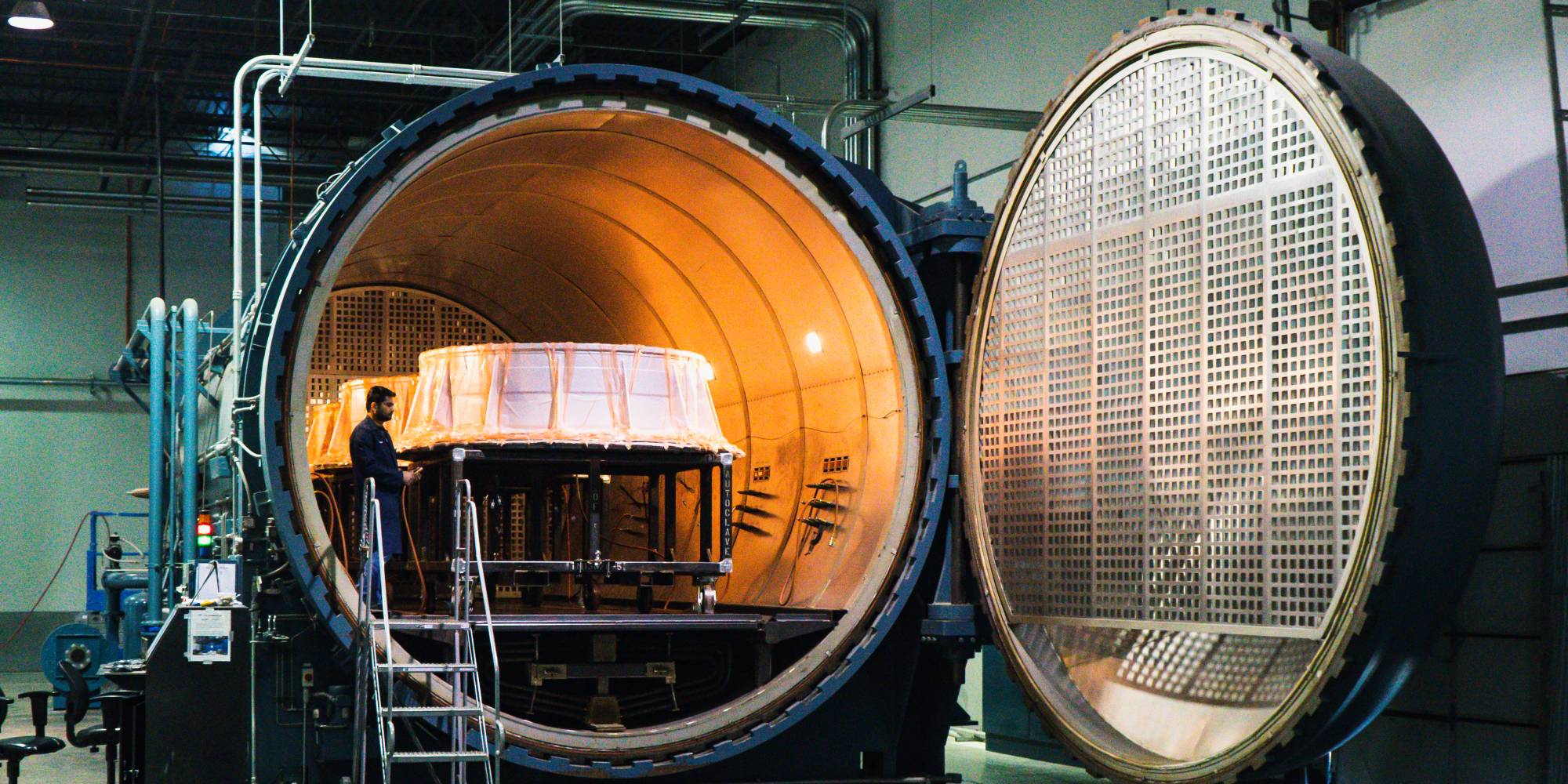

This state-of-the-art facility includes automated material cutters, 5-axis waterjet machining, CNC machine centers, Automated Systems Controls (ASC) for our ovens and autoclaves, NDT, as well as class 100,000 clean-rooms.

- Autoclave Molding

- Compression Molding

- Resin Transfer Molding

- In-House Machining

- Assemblies

- Bondments

Autoclave Molding

- Sandwich Structures

- Metal Bonding

- High Temp Processing

- Filament Winding

- Soluble Tooling, Rapid Prototype

Compression Molding

- Sheet Molding Compound

- Bulk Molding Compound

- Prepreg

Resin Transfer Molding

This process involves generating a preform from a dry or slightly tackified fibrous reinforcement. Then it is placed in the mold cavity. Once enclosed air is evacuated from the structure and the catalyzed matrix resin is introduced at a controlled rate. CTL has ten single component injection systems which are ASC processor controlled.

Sandwich Structures

These composite structures are composed of a lightweight core, usually honeycomb or structural foam, encapsulated by thin, structural skins. CTL has the capability to produce both flat and highly controlled contoured sandwich structures.

Bondments & Assemblies

In-house Machining

Capital Equipment & Facilities

Quality Assurance

Our Certifications:

- NADCAP

- AS-9100D